Edge tuning

Tuning of the edges involves the following working steps:

1. Examine the base

2. Tuning the base edge

3. Tuning the side edge

4. Edge finish

5. Edge repair.

1. Examination of the base

The running face should be inspected using the HOLMENKOL straight edge true bar. The following pictures can occur:

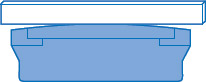

1.1 Concave base:

1.1 Concave base:

Base hollow towards the middle. Ski/board

rests on the edge, is therefore difficult to

turn and tends to cut.

1.2 Convex base:

1.2 Convex base:

Base curved towards the outer edges.

Edges have poor contact. Ski/board feels

difficult to establish good edge grip &

control.

1.3 Flat base:

1.3 Flat base:

The tread is plane from edge to edge. Ski/

board rests on the ski base and edge and

is easy to control/turn with the right edgetuning.

If the ski/board is not perfectly flat, we recommend that you have

the ski/board ground plane by a qualified ski service shop.

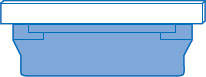

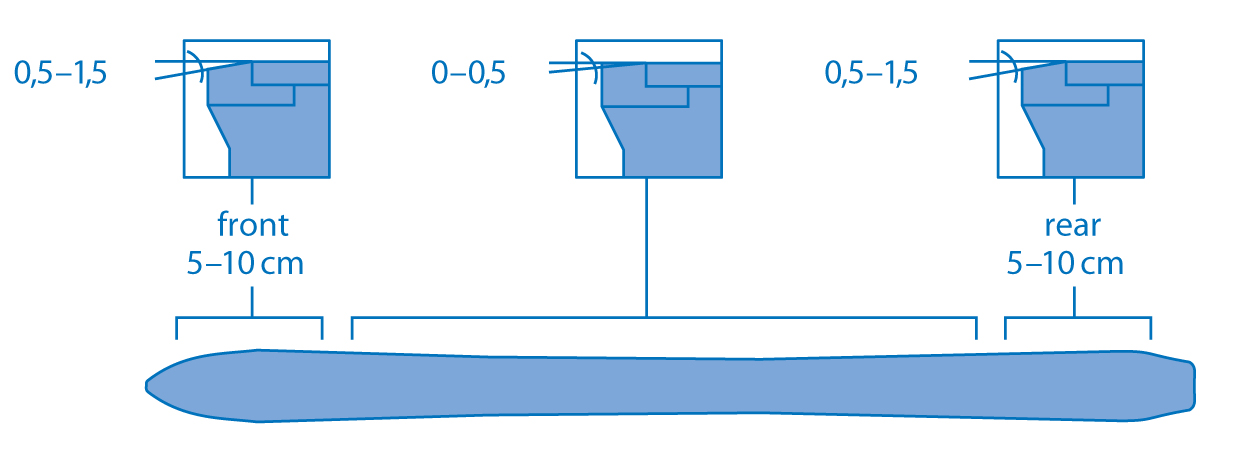

2. Tuning of the base edge (hanging cut)

The base edge should be prepared using the HOLMENKOL Base- Edge FileGuide, with slightly greater base edge angle at the tip and tail to aid in smooth turn initiation.

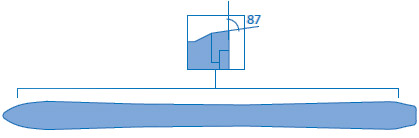

3. Side Edge Tuning (=back cut)

The side edges are precisely relief-ground using edge grinders. The side edge angle is prepared depending the discipline (e.g. downhill/Super G/giant slalom: 88°– 87°, special slalom 88°– 86°).

4. Edge finish

Freshly ground and extremely sharp edges at the end of the ski/ board and in the blade area prevent the ski/board from turning easily and lead quickly to errors. For this reason, the edges in the front and rear area are slightly eased over a length of 5 to 15 cm. The edge grip is maintained and the ski/board is easy to handle in

turns. Edges at the front and rear end of the ski/board, which have nothing to do with the ride characteristics of the ski/board (the part of the edge which has no contact with the track by a straight position of the ski) should be rounded.

5. Edge repair

Stones on the track can cause hardening in the edge as the contact between edge and stone briefly generates a great heat. The surface of the edge is changed as a result and it becomes more dense than the surrounding material. These spots are very difficult if not impossible to remove with conventional files. Inaccurate work is the result. These hard spots can only removed by using the Diamond File blue or the Aluoxyd stone. Finish with the Diamond File green or red.